Function

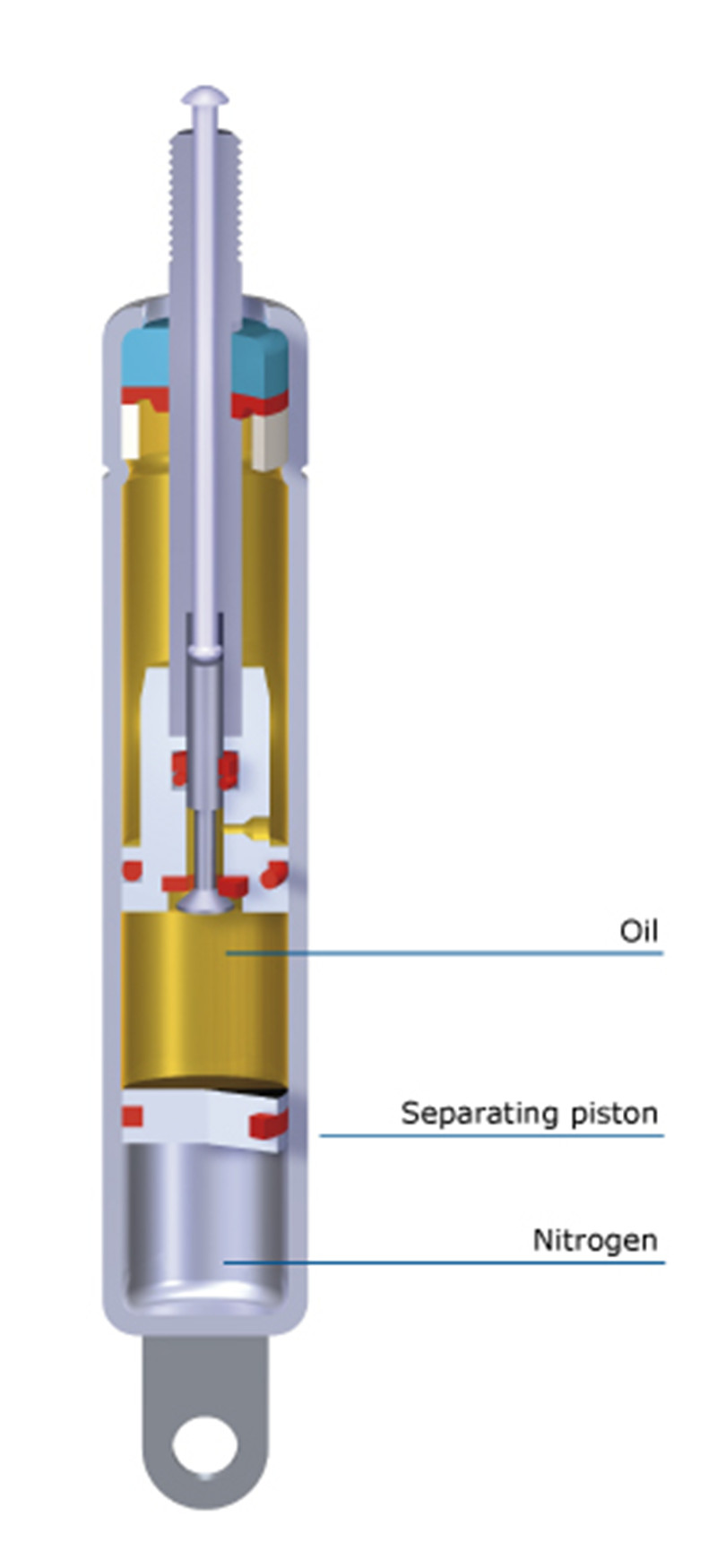

Unlike the purely gas-filled, elastic locking standard BLOC-O-LIFT spring, the entire stroke is filled with oil in this version, allowing rigid locking. A special separating piston separates the gas chamber from the oil chamber. Depending on the type, this will provide different locking forces in the extension direction (tensile lock) or in the compression direction (compression lock).

As an added advantage, the gas spring can be installed in any position.

Advantage

● Very high oil locking force

● Can be installed in any orientation

● Variable locking and optimized weight compensation during lifting, lowering, opening, and closing

● Compact design for installation in small spaces

● Easy mounting due to a variety of end fitting options

Application Example

● Head and foot panel adjustments in hospital beds, operating tables, wheelchairs

● Height adjustment in walker

● Armrest, headrest, driver seat adjustment

● Desktop/table height and inclination adjustment

● Very high oil locking force

● Can be installed in any orientation

Unlike the purely gas-filled BLOC-O-LIFT, where the gas characteristics s cause spring locking. in this type of BLOC-O-LIFT is filled entire working range of the piston is filled with oil. Depending on the installations-called separating pistons, which sepa-rate the gas chamber from the oil chamber different locking forces can be achieved in the extension or compression directions. The maximum allowable locking force depends on the extension force and/or the Overall device strength.

Different Rods

Rods can have different characteristics once they are locked. They can be, for instance, flexible, which means they are very resistant when being pulled or pushed. They can also be rigid in tension: there is no flexibility if rods are being pulled but there is a slight flexibility if they are being pushed. Finally, they can be rigid in compression if they are a bit flexible when they are being pulled but not when they are being pushed.